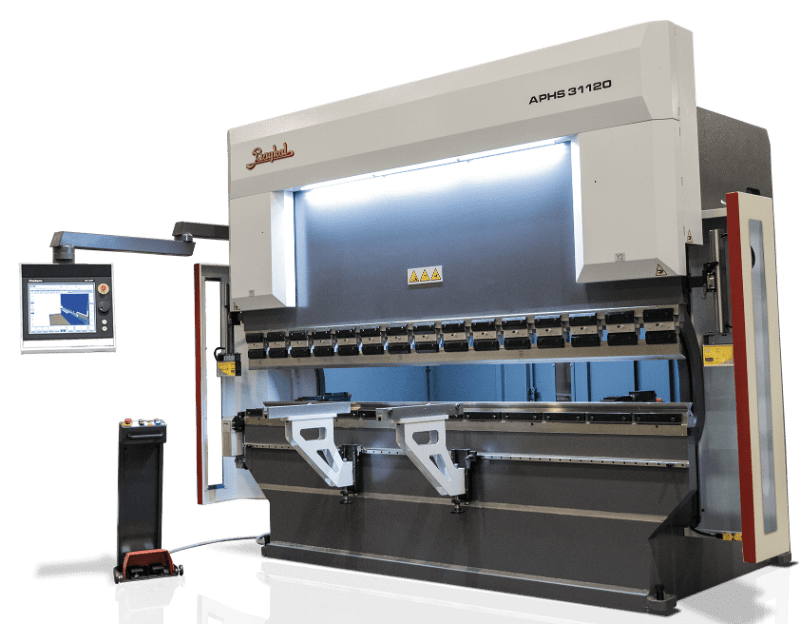

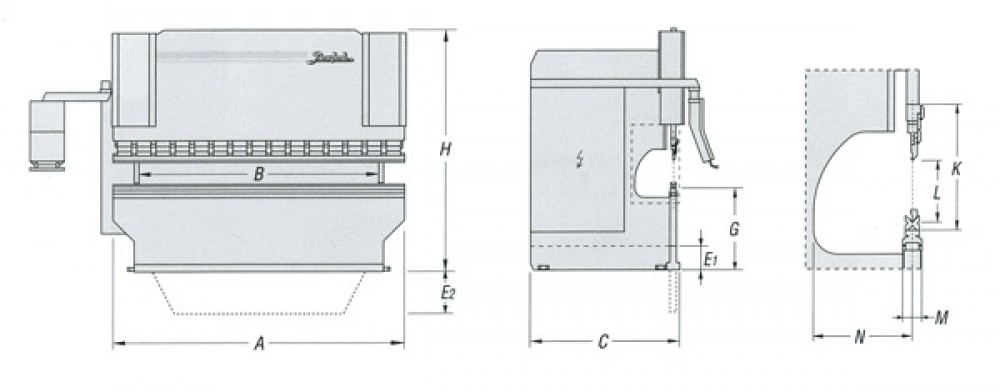

APHS PRESS BRAKE

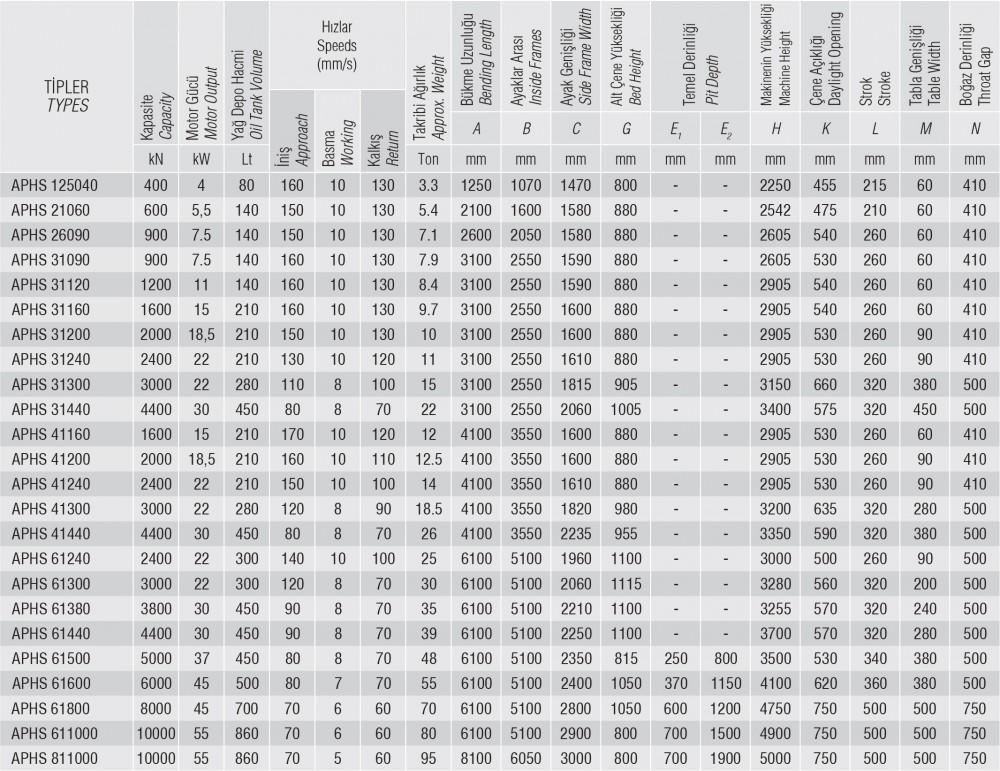

Baykal APHS Press Brake Capacity

Bending length from 1250mm to 6000mm, bending capacity from 40 tons to 1000 tons, distance between feet from 1070mm to 6050mm, throat depth from 410mm to 750mm.

Baykal APHS Press Brake General Features

Monoblock, welded body with static and dynamic rigidity. Down-moving bending system with precision honed cylinders made of high-grade forged steel. Upper jaw movement supported by low friction fiber slide bearings. Fully electronic balancing synchronization integrated with proportional valve technology: As a result of continuous monitoring and adjustment of jaw parallelism by means of CNC control system, maximum bending precision and identical bending of parts one after another are provided. Precise stroke depth control via linear scales. CNC controlled backgauge system with DC-motor drive, moving on ball shafts. Block-type European hydraulic equipment. Ventilated, compact designed electrical panel. Full compliance with the European Union Machinery Safety Regulation and certified CE label