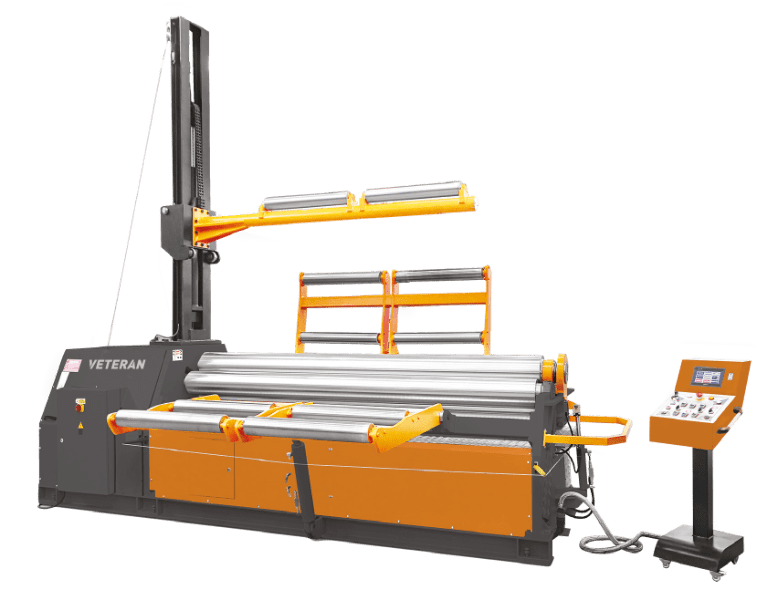

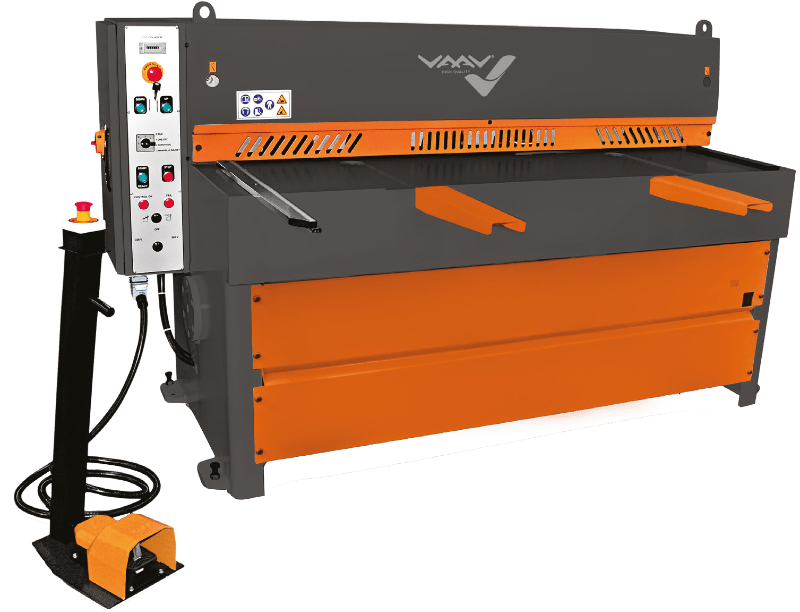

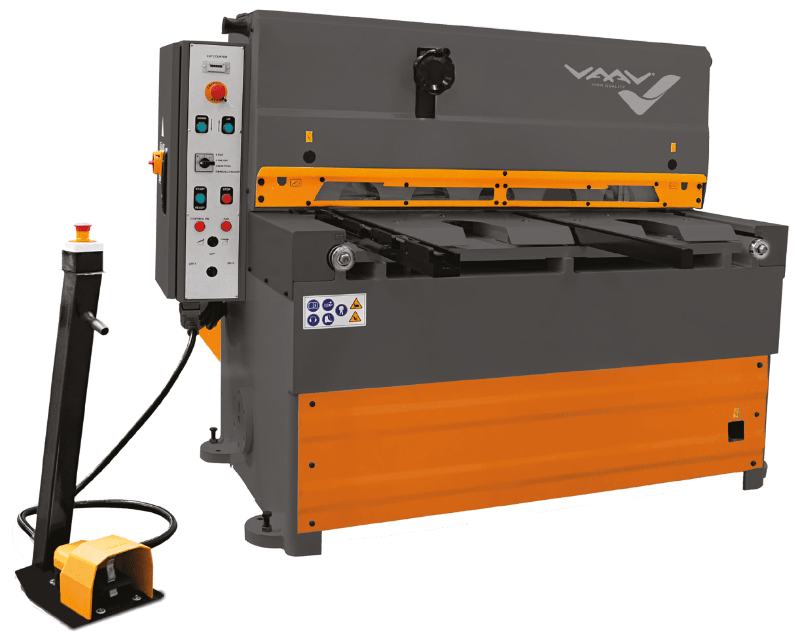

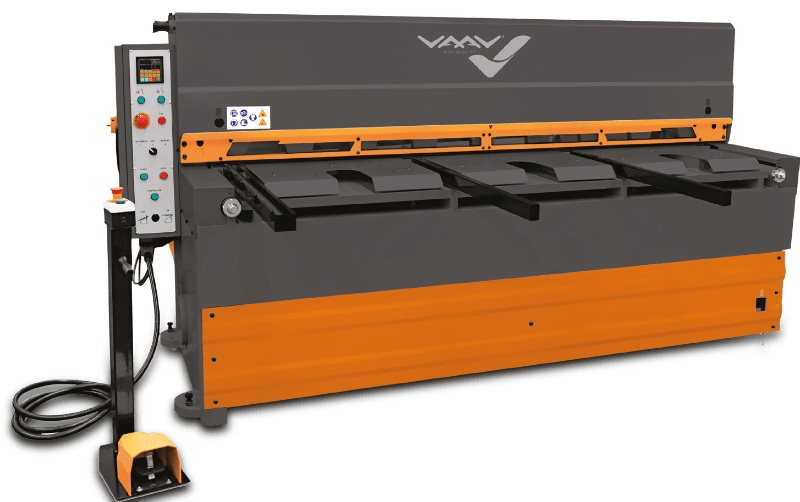

V HMS

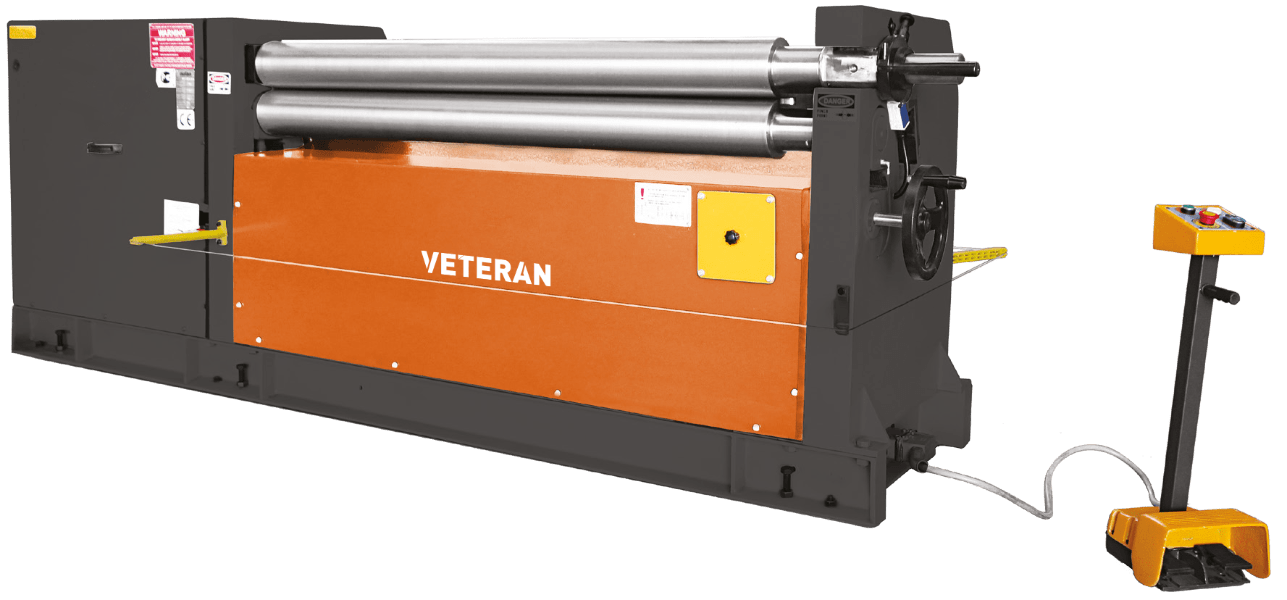

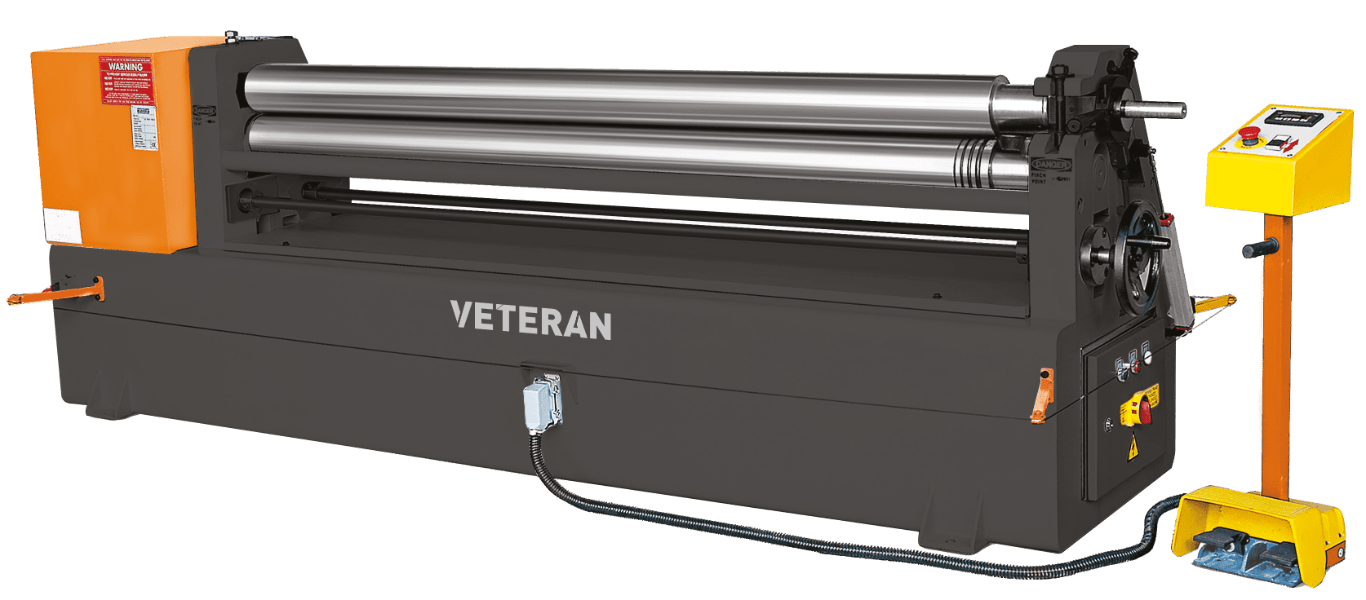

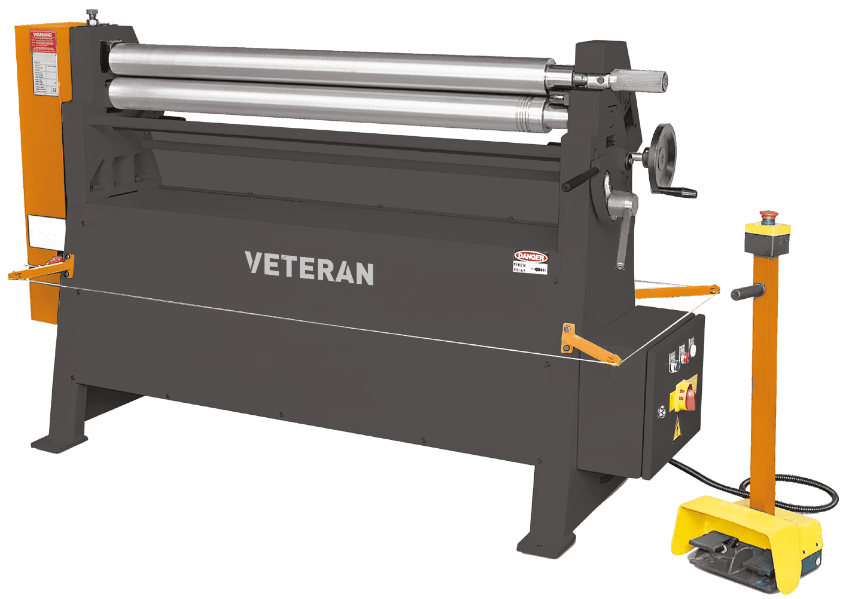

HYDRAULIC PLATE ROLLER General Features

Used for small scale wheels, exhaust, fuel tank production. They are also used in many sectors such as tanker, silo, ship industry as HHPRM models. These models have single motor, single reducer, single torque motor. The power generated by the large electromotor that activates the lubrication system and provide direct drive to gearboxes. Torque motor gives movement to shafts. Back roll rotates with the material. All rollers use a moving-ball bearing, which allows orbital movement. The digital display on the control panel allows the reading of the position of the side balls and the bottom ball, also cut off point adjustment can be made.

HYDRAULIC PLATE ROLLER Standard Specifications

Designed for bending light and medium steel plates, aluminum or stainles steel plate , Designed for bending circle, conical, elliptical, and varying radiuses shapes , Pinch roll and lateral rolls moved linear by direct coupled hydraulic pistons, Overload protections system, Pinch roll is driven with electrical motor and planetary gearbox. Bottom roll is driven with cardan joint system, Rolls positions can be seen by digital readout, Bended part can be easily removal by hydraulic tiltable drop end., Mobile control panel is used for easy operation, Body made from welded steel construction, Rolls are forged or rolled steel(CK50) hardened with induction, Cone bending device, Hydraulic balancing system provides paralel driving for rolls, Double speed operating system.