Lathe

The lathe machine is an indispensable product in many fields, especially in the furniture sector, and helps to minimize manpower. With the development of technology, lathe machines have gained different features and the change of these features positively affects the work flow of other sectors as well as the furniture industry. The lathe machine rotates around its axis so that it can remove chips on a metal part and perform operations in a short time. In order for the lathe to work correctly and effectively, a suitable lathe is needed. To make your operations more practical, you can create a suitable area for the use of the lathe.

Top Quality Lathe Types at Emektar Makina!

Turning is an important process in many industries, especially in the metal sector. Machining is used to remove defects on the surface of objects with round geometry. For this operation, the object is rotated and controlled by hard, sharp diamond tips. In this way, defects on the surface are removed by removing chips. The turning process is ideal for making the surfaces of damaged metals reusable. It can also be applied to wooden and plastic elements. The devices used for turning are known as lathes.

What are the Usage Areas of the Lathe Machine?

The lathe machine is a product that is widely used in many business sectors and helps to overcome the most difficult operations thanks to its practical use. Today, lathe machines are used in many areas that are needed by developing and developing sectors. For example, the furniture industry is one of the industries in which turning machines are most commonly used. The fastest and most practical way of assembling, cutting and shaping the iron and similar parts of the furniture is the use of a lathe machine. Therefore, turning machines are an indispensable need in the furniture industry. In addition, turning machines, which are frequently used in other sectors such as wood turning operations, are also needed in areas such as glass processing, thermal spraying, metal spinning and metalworking. It is possible to speed up your production processes if the lathe machine is adjusted and used according to your business sector.

What Does a Lathe Machine Do?

A lathe is a machine generally used for shaping and processing metal, wood, plastic and similar materials. During the rotation of the materials, a cutting tool (usually a knife) is passed over the material. In this way, the material can be brought into the desired shape and size. Lathes are used in many industries such as the furniture industry, the automotive industry, aerospace, machine manufacturing and metalworking. It is also used in processes such as woodworking, glassworking, thermal spraying and metal spinning. The functionality of the lathe, its practical use and its use in many sectors made it an indispensable tool in industrial production processes.

Wood Lathe Machine Models

A wood lathe machine is a device that cuts wood materials into predetermined sizes and shapes. This tool, also known as a wood lathe machine, rotates the wood piece and cuts it in the same size and shape as the other piece with the help of a cutting tool. It performs wood processing in a fast and efficient way, allowing wood materials to have a smoother appearance. Wood lathe machine spare parts, on the other hand, are the products necessary for the efficient use of the machine. Therefore, in case of any malfunction in the machine, it is necessary to provide spare parts. Providing spare parts helps processes go faster and improves work efficiency.

How Should Wood Lathes Be Used?

The wood lathe machine can be easily used by anyone who is familiar with woodworking. Today, with the rapid development of technology, computer-controlled lathe machines are also available in the market. Thanks to these machines, the designs made on the computer are transferred directly to the wooden part and the cutting operations are carried out precisely. Especially the lathe machines used in the production of wooden furniture are ideal for parts that require detailed and careful work. With proper planning and use, mistakes can be avoided and excellent results can be achieved.

Wood lathe machines provide great convenience to their users thanks to their easy control. In addition, they are very simple to clean, and with these features, they save both time and effort. These machines, which are a great help in the production processes, provide great convenience to the manufacturers by reducing the labor force significantly. Wood lathes, which you can use anytime, are an indispensable tool for those who are passionate about woodworking.

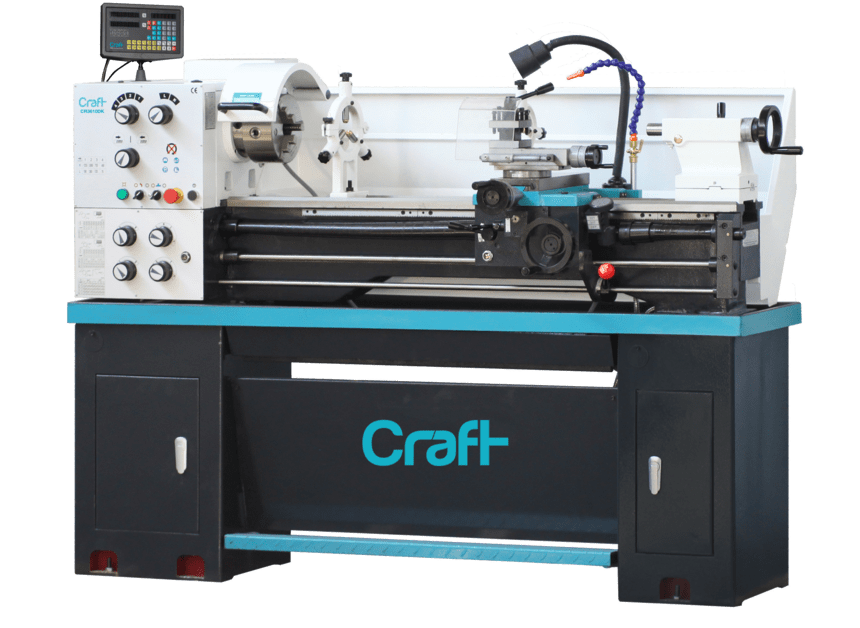

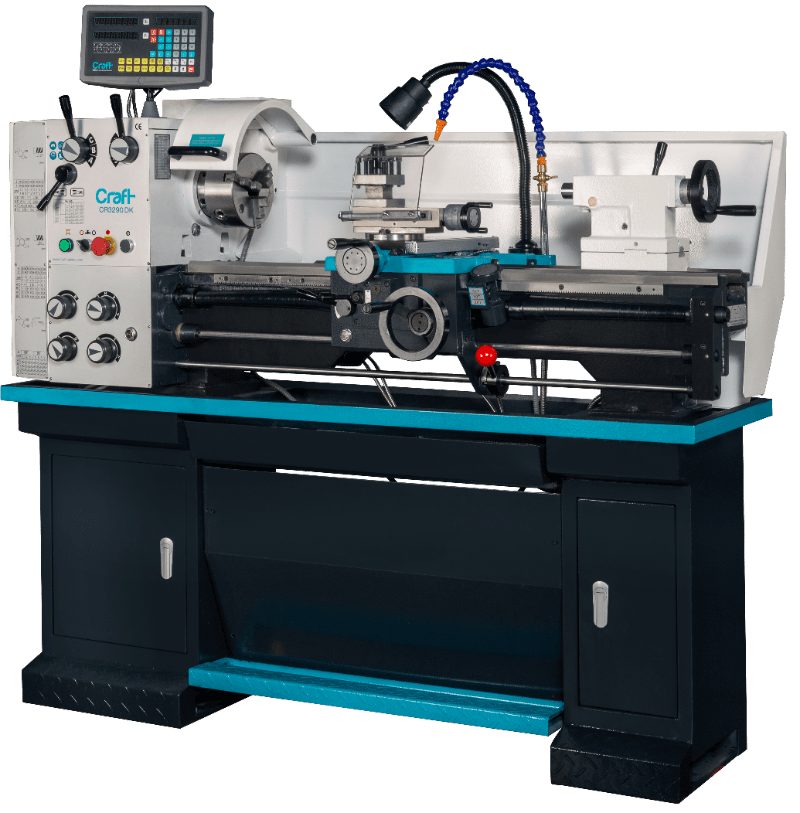

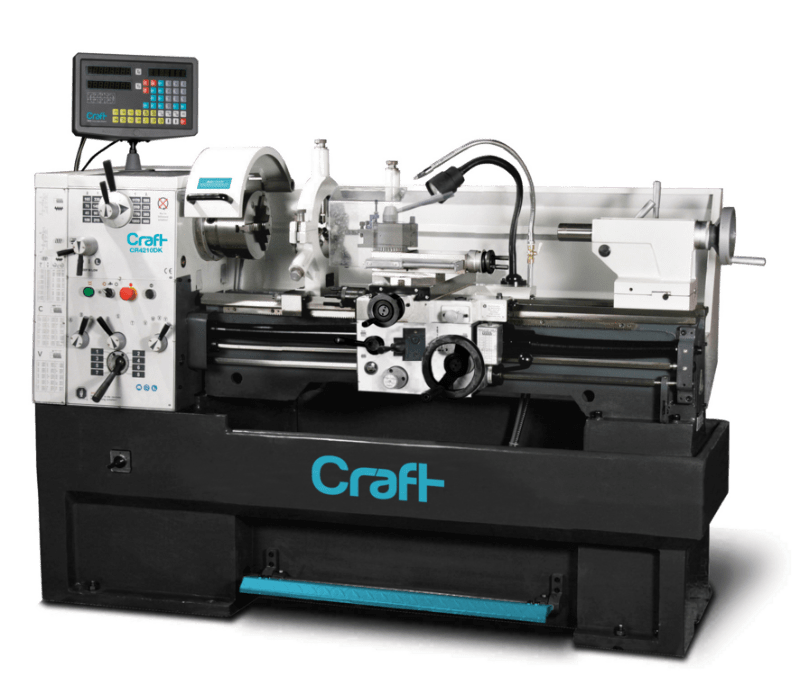

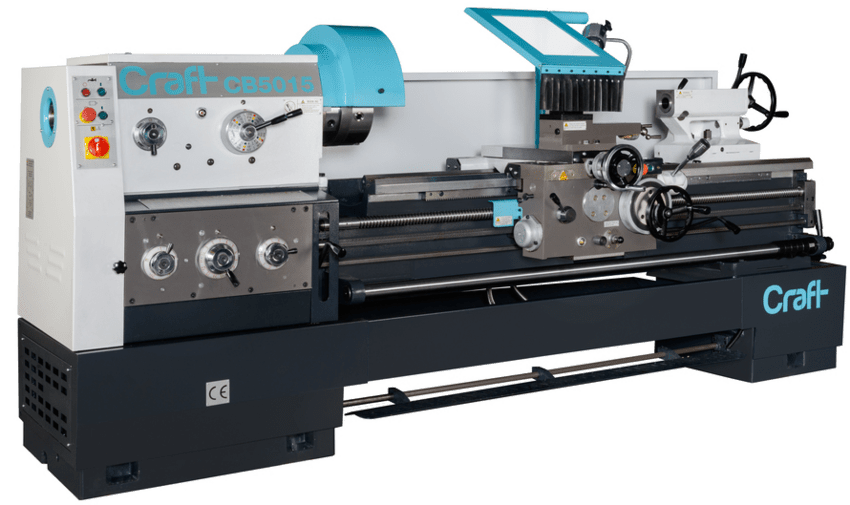

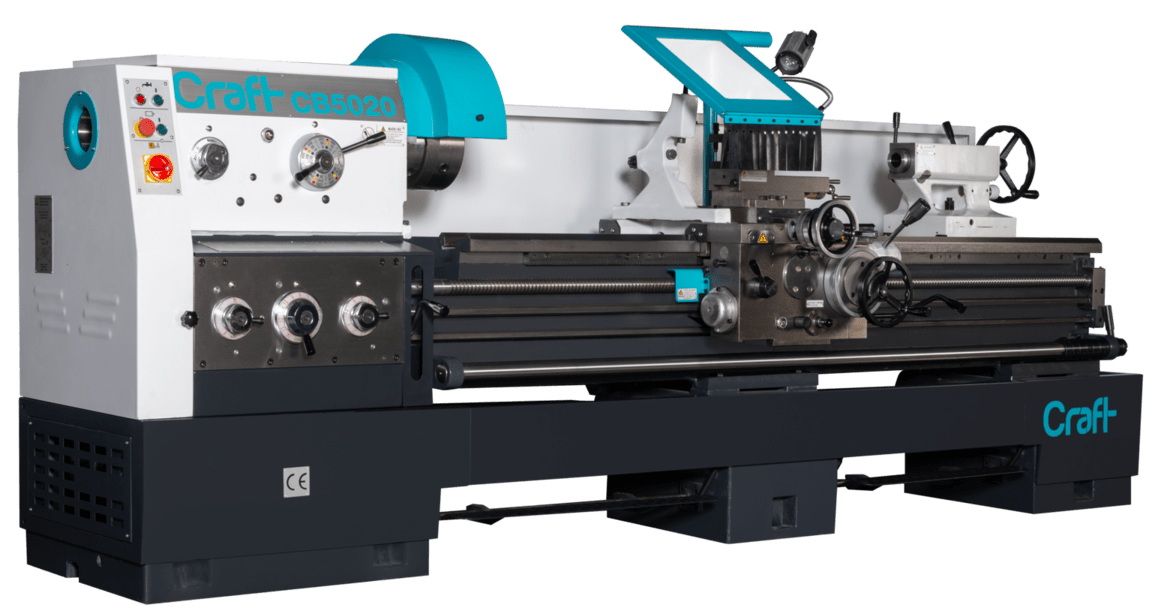

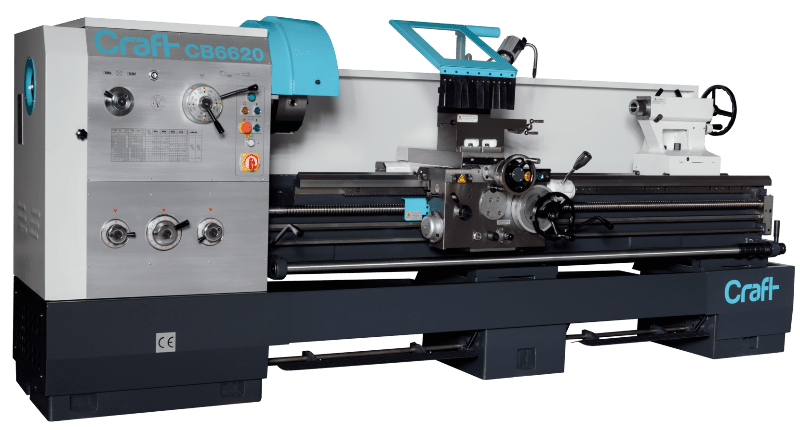

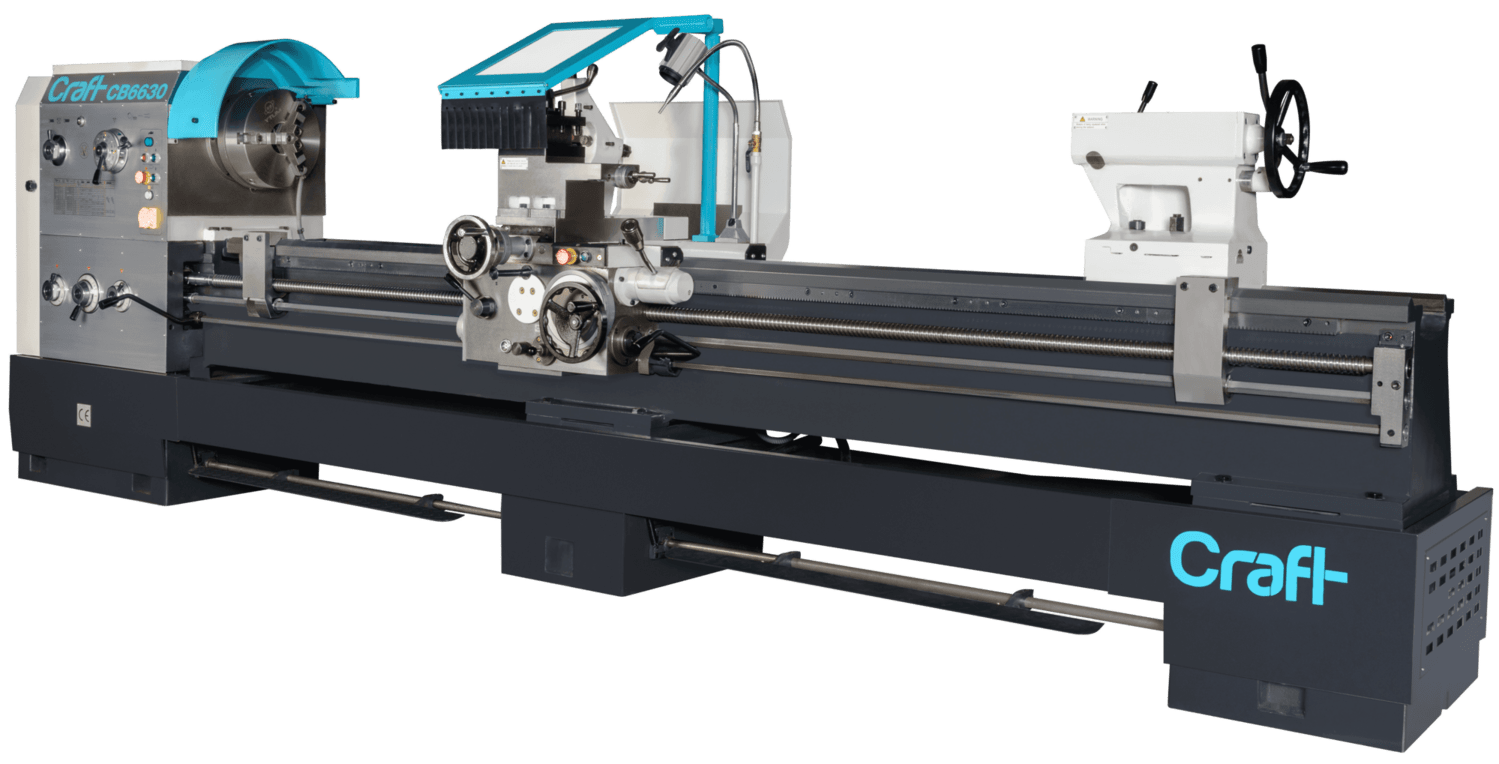

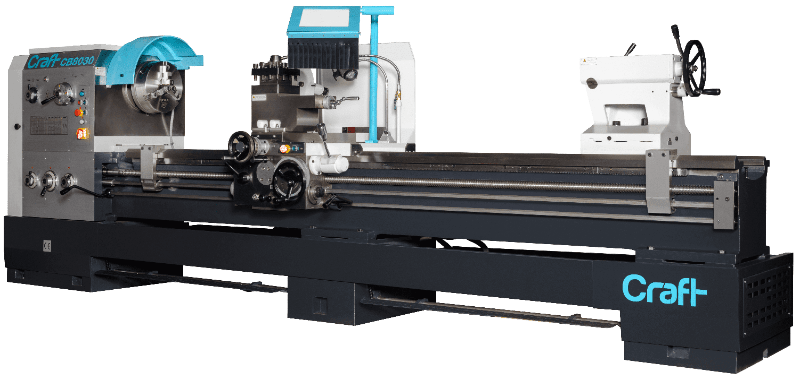

Metal Lathe Machine Models

Many people who work in the technical and engineering fields know that turning is mostly applied to metal materials. “What does a metal lathe machine do?” Every user looking for the answer to the question must first learn in detail how the turning process takes place. The turning operation is performed slowly and precisely. During this process, chips of equal thickness should be taken from all surfaces of the rotating part. The depth of the chip should be constantly checked and rapid movements should be avoided during this process. Because metals are extremely hard, this process should be done slowly and carefully. For machining metals with a lathe, a harder material than diamond tool steel should be selected. Applications made in this way can be completed without any problems. Starting from steels, turning operation can be applied for almost any metal. However, working on soft metals is not always easy. It is important that the metal does not deform easily during this process. Tool steel selected from hard materials allows the chip to separate from the surface when it comes into contact with the metal surface. Therefore, it should be noted that soft metals such as copper and iron with a high percentage of purity are not suitable for turning.

What is a Lathe? How should it be used?

The use of the lathe is very simple and everyone can easily use the lathe after gaining practicality. The use of lathes may vary according to the preferred model. Some lathes are computer controlled, while others can be operated manually. Therefore, you can apply the appropriate use method according to the lathe model you prefer.