Jetco Lathe Types and Features

Jetco is a leading brand in industrial turning processes. Jetco’s various lathe models are used effectively in parts production with features such as high precision, efficient processing speed and durability. In this article, we will explore Jetco’s important models: JML 3010Y, JML 3510Y, JML 3610Y, JML 4110Y, JML 5010B, JML 5015B, JML 5020B, JML 6620B and JML 6630B lathes. These models appeal to various industrial applications by offering different features and capacities.

JML 3010Y Lathe:

The JML 3010Y is a compact and versatile lathe model from Jetco. With its portable design and user-friendly interface, it is ideal for small and medium-sized parts production. The powerful spindle and precise control systems that provide high-precision machining ensure that parts are machined in the correct size and shape. JML 3010Y is generally preferred in the production of precision parts used in the automotive, electronics and medical industries.

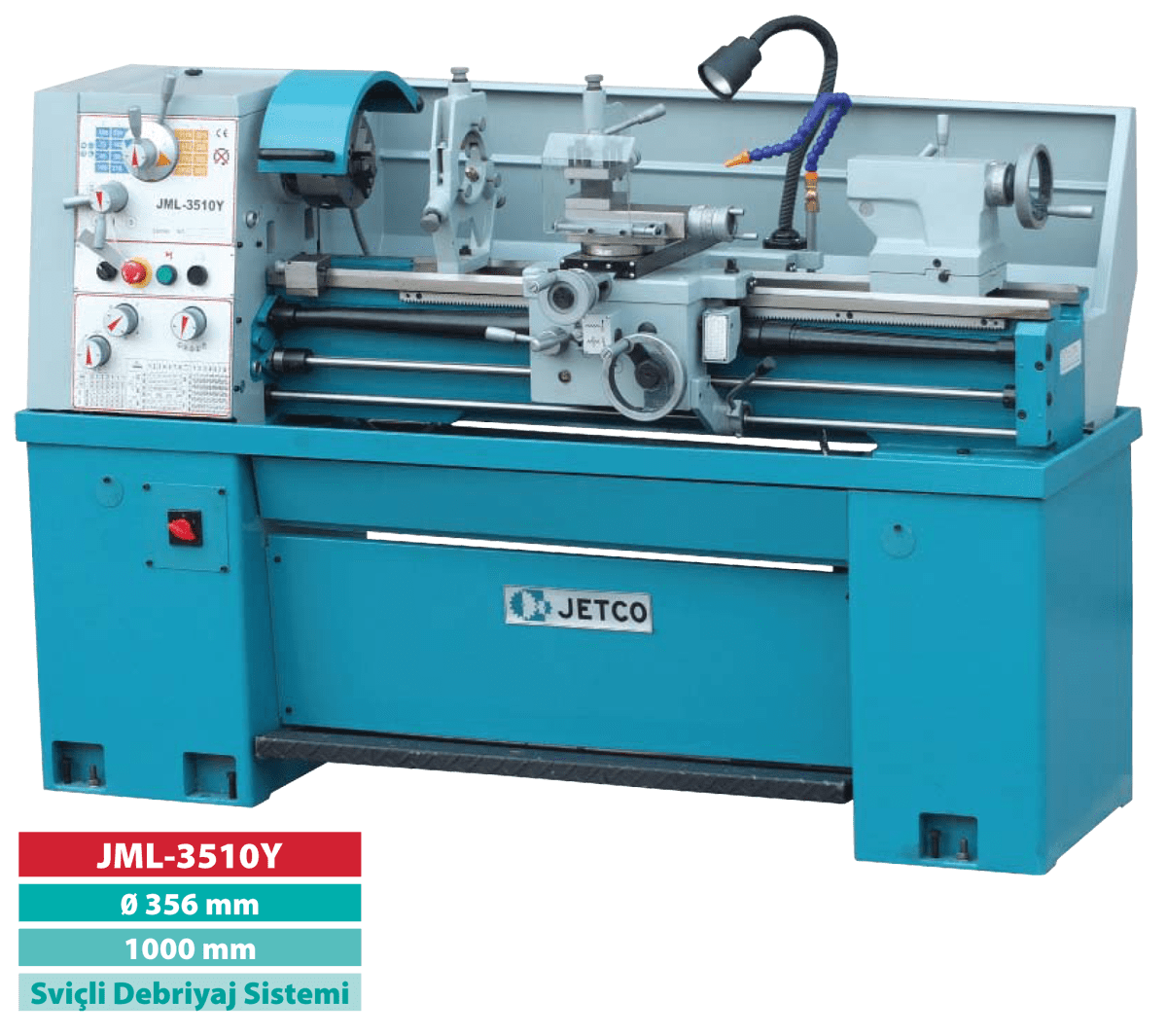

JML 3510Y Lathe:

The JML 3510Y is a lathe model from Jetco designed to meet medium-sized machining needs. Powerful spindle and high-efficiency control systems provide fast and precise processing in part production. JML 3510Y is used in a variety of industries thanks to its ability to process a wide range of materials.

JML 3610Y Lathe:

JML 3610Y is one of Jetco’s high-end lathe models. It is used effectively in the production of large and complex parts with its high-performance spindle, control systems that provide precise machining, and large processing capacity. The JML 3610Y is ideal for the production of complex parts often in demand in industries such as aerospace, energy and defense.

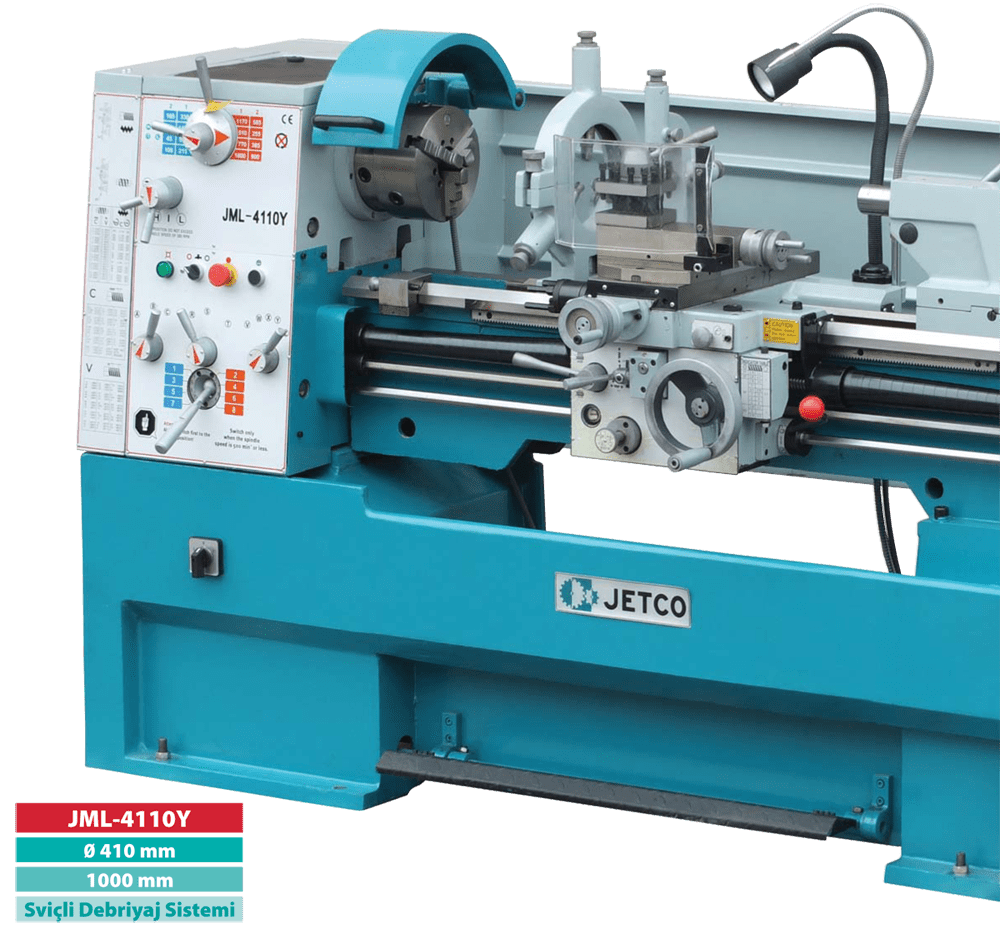

JML 4110Y Lathe:

The JML 4110Y is a lathe model from Jetco designed for large-scale parts production. The high-power spindle and stable machining capabilities are effectively used in machining large and heavy parts. JML 4110Y is ideal for the production of large parts used in areas such as shipbuilding, mining and the energy sector.

JML 5010B Lathe:

JML 5010B is Jetco’s lathe model. High-speed machining and automatic programming features are suitable for mass production and part production requiring repeatability. JML 5010B is a popular choice for the production of parts used in industries such as automotive supply industry, electronic components and machinery manufacturing.

JML 5015B Lathe:

JML 5015B is Jetco’s model. Its high precision and efficient machining capabilities are effectively used in small and medium-sized parts production. JML 5015B is preferred for the production of precision parts used in various application areas such as automotive, aerospace and medical industries.

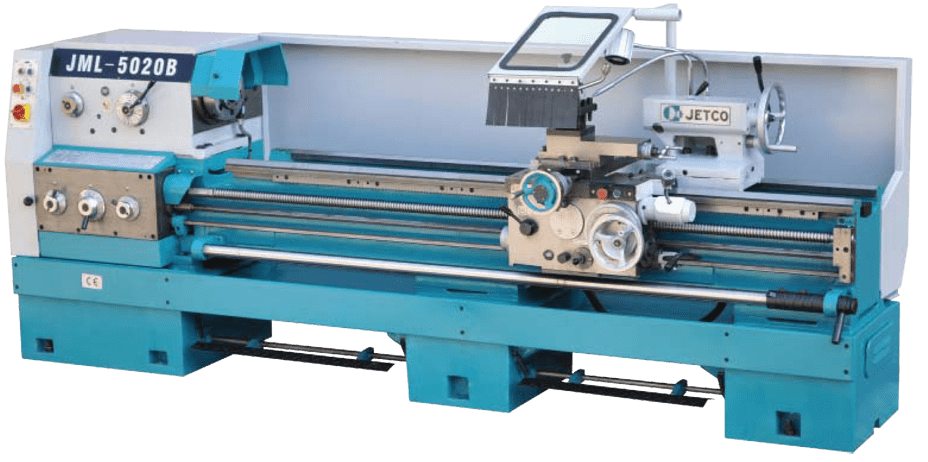

JML 5020B Lathe:

The JML 5020B is Jetco’s mid-sized lathe model. Powerful spindle, high machining efficiency and precise control systems enable precise machining of parts used in various industries. JML 5020B is ideal for the production of parts commonly used in industries such as automotive, aerospace, energy and electronics.

JML 6620B Lathe:

JML 6620B is a lathe model from Jetco designed for the production of large-sized parts. High machining capacity, powerful spindle and precise control systems enable precise machining of large and complex parts. JML 6620B is an ideal option for the production of large parts used in industries such as shipbuilding, aerospace and energy.

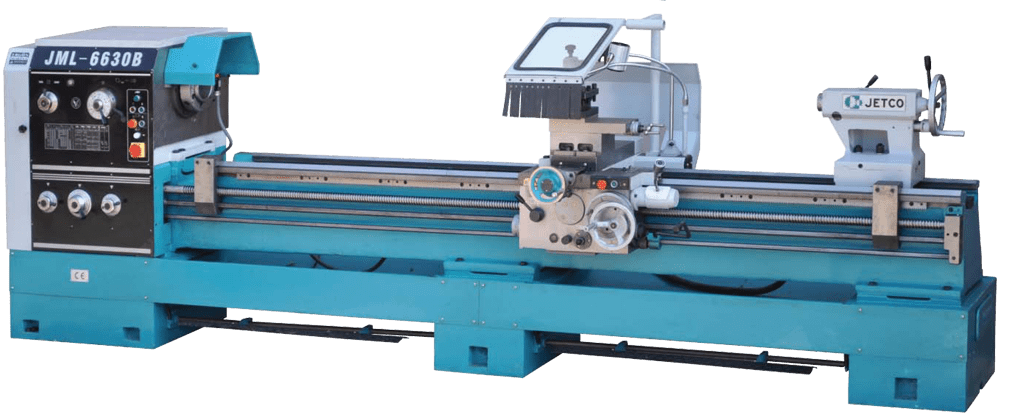

JML 6630B Lathe:

The JML 6630B is Jetco’s high-end lathe model. It is effectively used in the production of large and complex parts with its high-performance spindle, precise control systems and large processing capacity. JML 6630B is ideal for the production of large parts used in sectors such as the defense industry, energy and aerospace.

Jetco’s various lathe models offer the precision, efficiency and durability required for industrial parts production. JML 3010Y, JML 3510Y, JML 3610Y, JML 4110Y, JML 5010B, JML 5015B, JML 5020B, JML 6620B and JML 6630B lathes are ideal options for the production of parts used in different scales and application areas. Jetco’s quality engineering and innovative designs provide customers with a reliable solution to meet their industrial turning needs.